|

One of

the most important elements of the Flowdrill

process is the use of specified rotational speeds

or RPMs. The Flowdrill process requires higher

speeds than conventional drilling methods. Speed

requirements are influenced by the hole diameter,

material thickness, and the type of

material.

- Rotational speed requirements range from

1000 to 3500 RPMs.

- Motor power requirements range between

1.5 and 3.5 kWs.

|

|

|

|

| |

|

|

|

|

|

Feed is

the rate that the Flowdrill advances into the

material. Manual, Steady or Variable feed rates

can be applied depending on the machine’s

capabilities. Flowdrill has tables to help you

determine the optimal feed values depending on

your material type and

thickness. | |

| |

|

|

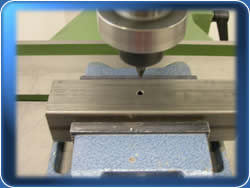

Axial

Force

Axial Force is the

downward pressure exerted on the material as the

Flowdrill advances into the workpiece. Thin

materials may bend or collapse under excessive

pressure. Adequate support must be provided to

prevent deformation. A pre-hole or a Fluted

Flowdrill may also be used to facilitate the

initial entry into the workpiece with reduced

axial force.

|

|

|

| |

| |

|

| |

|

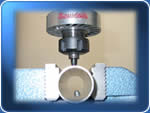

Toolholders

The MC2

and MC3 Toolholders insure the optimum clamping of

the Flowdrills and prevent rotational slippage

while the tool is turning at high speeds. Multiple

prongs in the Collet securely hold the Flowdrill

in a 360° clamping system. The Toolholders use a

built-in aluminum cooling disc designed

specifically to diffuse heat that travels up the

spindle. The Toolholders use a standard tapered

shaft that will fit most standard drilling

systems. A cylindrical shaft is also available for

CNC machines.

|

|

| |

|

|

Lubrication

To optimize the quality and precision of

the hole, lubrication needs to be applied prior to

each perforation. Lubrication can be done by hand

or with automatic spraying systems.

|

|

|

|

| |

|

|

| |

|

Preholes

Preholes can be used to reduce the axial force

or to reduce the total length of the formed bush.

Using a prehole also produces a smooth finish in

the bushing’s lower edge. Reduced axial force may

be required to avoid bending thin materials (less

than1.5mm). |

|

| |

| |

|

Recommended Practices for Optimum

Results

- Use of equipment with the recommended

power and speed specifications

- Use of recommended Toolholders

- Regular inspection and adjustment of the

clamped Flowdrill tools

- Proper setting of the start (zero) and

final positions

- Use of recommended feed speeds according

to the type and thickness of material

- Proper lubrication of the Flowdrill

tool

- Secure and normal or perpendicular

clamping of the workpiece

|

|

|

|

|

|

|

| |

|